Spindles are essential in the advanced manufacturing world in which accuracy, reliability and speed are essential. It’s whether it’s sculpting aerospace-grade alloys or fine-tuning high-tolerance parts for medical devices the machining spindle will be the hidden force behind precision, speed, and consistency.

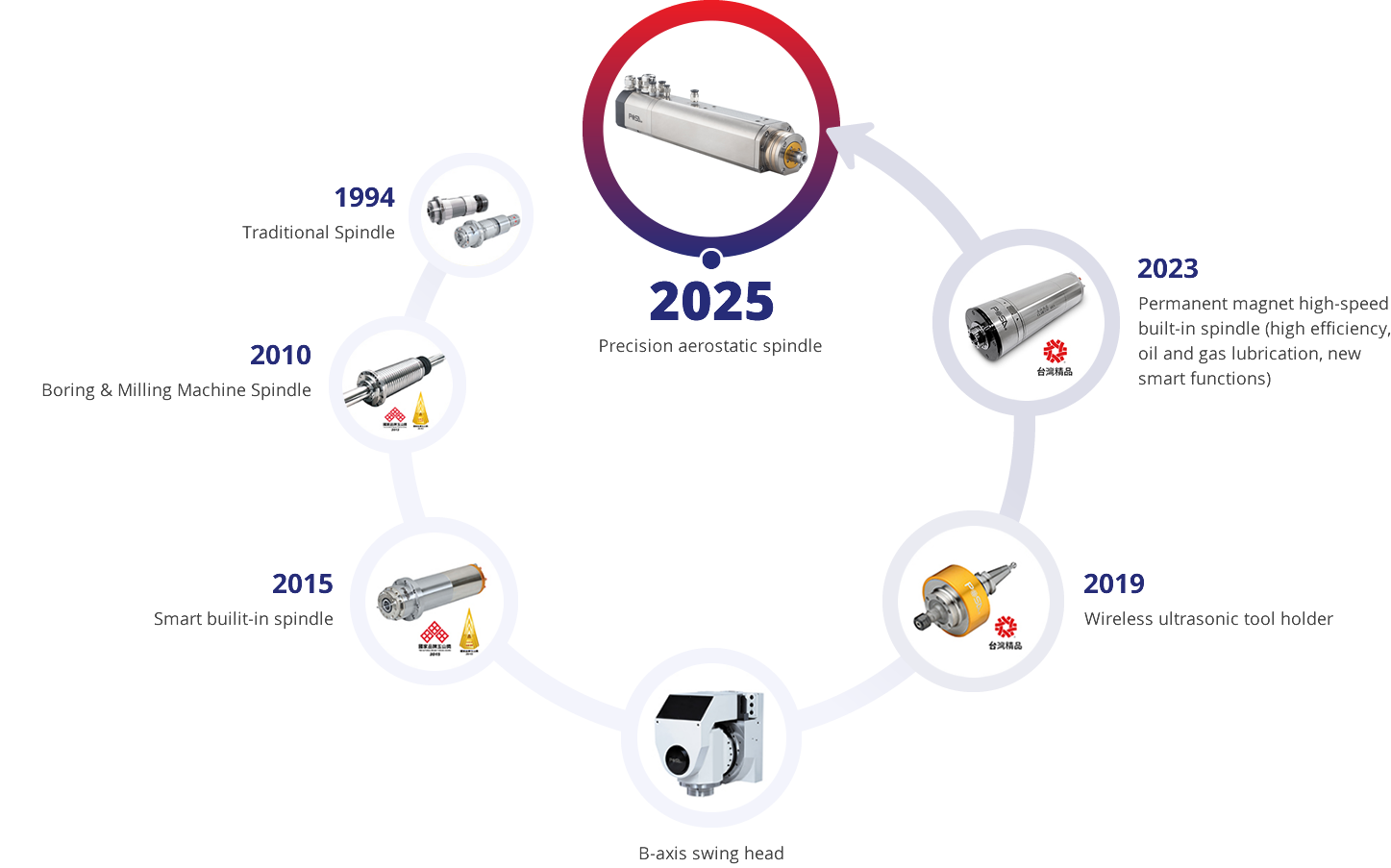

Top spindle makers such as POSA are at the forefront of this niche sector, redefining the performance and longevity of machines used in industrial environments.

Why the Spindle Is the Heart of the Machine

The quality of the spindle is the main element in every CNC machine. Imagine the spindle as the core of any CNC lathe, or machining centre. It powers the cutting tool at high accuracy, stability and torque. A poorly designed or misaligned spindle can result in faulty components but they also can cause damage to the machinery. This can reduce the life of the tools and disrupt the whole manufacturing process.

Image credit: posa-spindle.com

Precision spindle technology can be the key to a successful project. Precision spindles are different from standard components, are designed, tested and calibrated with care to meet the demands of high-demand and extreme conditions.

POSA Machine is More than a Spindle Maker

POSA is a spindle manufacturer which has earned a name for their high-quality. However, most spindle makers lack the experience and expertise in engineering that POSA can bring to the table. POSA is well-known for its rigorous internal test protocols, commitment to international standards and ability to create solutions that are performance-driven which meet the requirements of a variety of industries.

POSA spindles can be found in a myriad of machines, ranging from vertical and horizontal machining centres to tool grinding machines. Each spindle goes through an exhaustive R&D process that focuses not just on the performance of the spindle but also on its durability as well as thermal stability.

The Evolution of the CNC Lathe Spindle

The last few years have witnessed an amazing amount of creativity regarding the CNC spindle. Spindles are no longer just a rotating axe. They now incorporate sensors with cooling mechanisms, as well as sophisticated balancing mechanisms. The POSA CNC lathe spindles provide a wonderful example they combine high-speed capabilities and incredible rigidity and torque that allow machinists to handle both delicate materials as well as hard metals with no compromise on precision. Thanks to their superior ceramic bearings as well as high-quality construction, these spindles keep tight tolerances even over long runs. This reliability directly translates into greater quality of the part and less downtime.

Custom-designed Machining Spindles to meet Real-World Needs

There’s no universal machining spindle, especially in the fields of automotive, aerospace, and die & mold manufacturing. POSA is aware that each application will have its own specific requirements. This could be spindle speeds, load capacities as well as environmental resistance. So, they offer custom spindle designs that meet the specific needs of each client. When it comes to designing a spindle that can be used for vertical milling operations, or the integration of a high-frequency spindle in an efficient system, POSA provides the flexibility and engineering support that modern-day manufacturers require.

More Than Machines: A Commitment To Craftsmanship

The philosophy behind POSA’s spindles is what distinguishes it from other spindles. The POSA’s mission is a fusion of art and innovation. Their engineers listen to clients’ concerns and modify their products to accommodate changing marketplace demands. In an age where the machine’s uptime, accuracy and consistency can decide the fate of the production line, having the correct spindle is vital.

Final Thoughts

The future of manufacturing is not just on more efficient machines but additionally on components that are more efficient and reliable. POSA Machinery is a shining example of the results that can be achieved by spindle makers that combine their technical know-how and a strong emphasis on customer care. Whether you need a high-performance CNC lathe spindle, a heavy-duty machining spindle, or a finely tuned precision spindle, choosing the right spindle isn’t just a detail it’s a decision that shapes everything downstream.